Welcome to Heritage Clay Tiles Ltd, the UK's leading supplier of high quality handmade and handcrafted clay roof tiles, peg tiles and machine made tiles.

We pride ourselves on our high quality product range. Manufactured using traditional skills coupled with modern kiln technology, the Heritage Tile range is second to none, offering old world character and charm, yet able to meet modern, contemporary requirements.

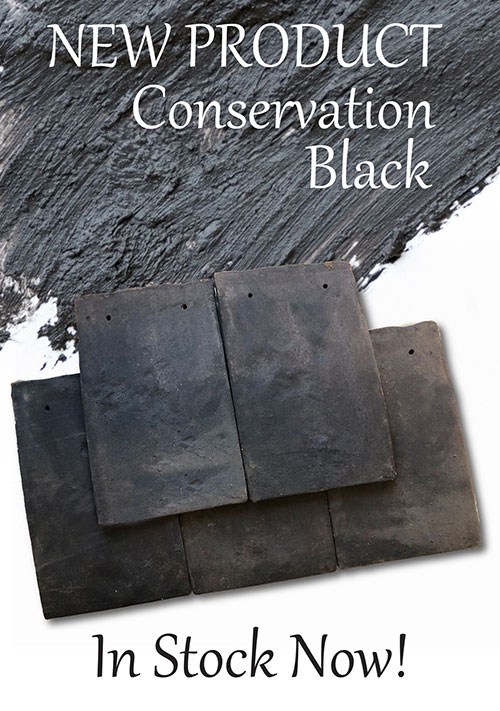

A wide colour choice, including innovative shades and bespoke styles is available, allowing the architect, specifier or homeowner complete versatility to create a stunning design that will enhance any project.